The environment

Resource-saving processes

Environment, safety and quality

We use latest machinery and equipment to minimise the carbon footprint CO2 of our facilities and employ highly efficient particulate retaining systems. Our pellets also help our customers to increase safety at their operations as a result of the dramatically reduced amount of explosive dust arising.

Safety, environmental protection and quality are the cornerstones of how we do business at CS Additive GmbH. Our success is based on our team’s untiring efforts and their strong commitment to our goals.

These values take us to our stated mission: Creating a safe working environment for our employees, acting responsibly and sustainably, and ensuring consistent product quality at the highest level.

Valuable products made from production waste

We are very aware of our responsibility for the environment. Therefore, we ensure that the raw material graphite stays within the production cycles wherever possible: Even today, two thirds of our annual output is already made from byproducts arising during the production and machining of our graphite products.

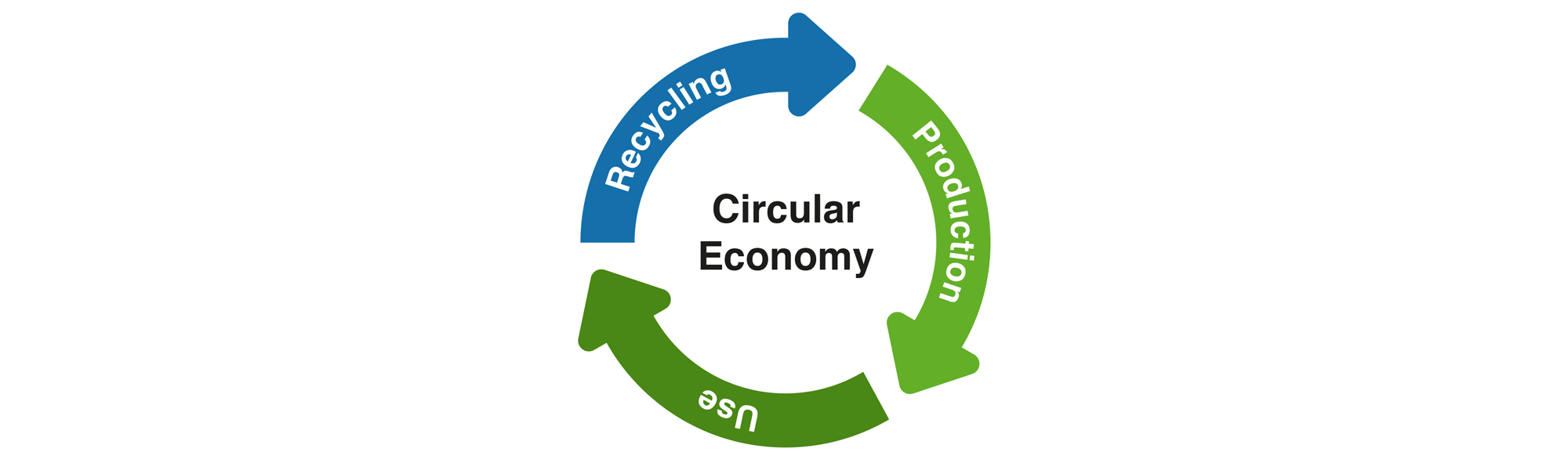

From leading manufacturers of graphite electrodes used in electric steelmaking, we buy electrode scrap that we further process in our grinding and sieving plants. We also use production waste from processes that involve the use of dust powder to make our high-grade pellets. All these measures help to reduce the amount of valuable primary raw materials consumed for carburising purposes. Thus, we are part of the circular economy, actively supporting the “3R” principle of Reducing, Reusing and Recycling: We reduce the consumption of natural graphite, reuse graphite in multiple ways and recycle graphite waste from production.